The FOCUS LaVa equipped with a 1 kW fibre laser housed in a 19″ rack. The two monitors are used to display the camera video and the CNC interface.

LaVa is the acronym for Laser welding under Vacuum and combines the strength of the laser with the vacuum environment.

Reduced pressure operation around 1 mbar allows for deep penetration welding and a significant reduction of spatters to nearly zero. Cu, Ti and many more materials can be welded with LaVa on an EB performance level which now becomes available for magnetic und insulating materials as well.

LaVa is available including a laser or configured to be used with an existing laser.

The two pairs of slow motion video clips are demonstrating the laser welding process for steel & copper performed at atmospheric pressure (1000 hPa) compared to vacuum conditions (1 hPa).

Laser power: 4kW, Welding speed: 0.5m/min, Framerate: 3000 fps

Features

Maximum Flexibility

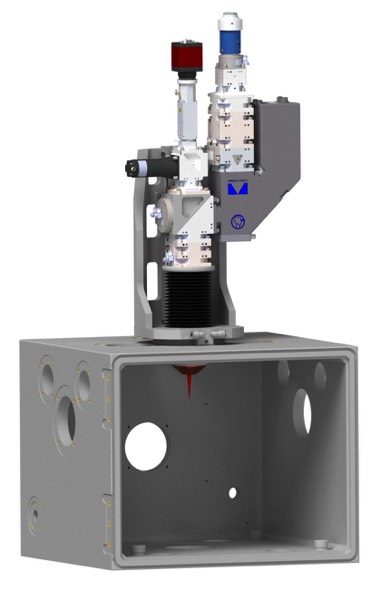

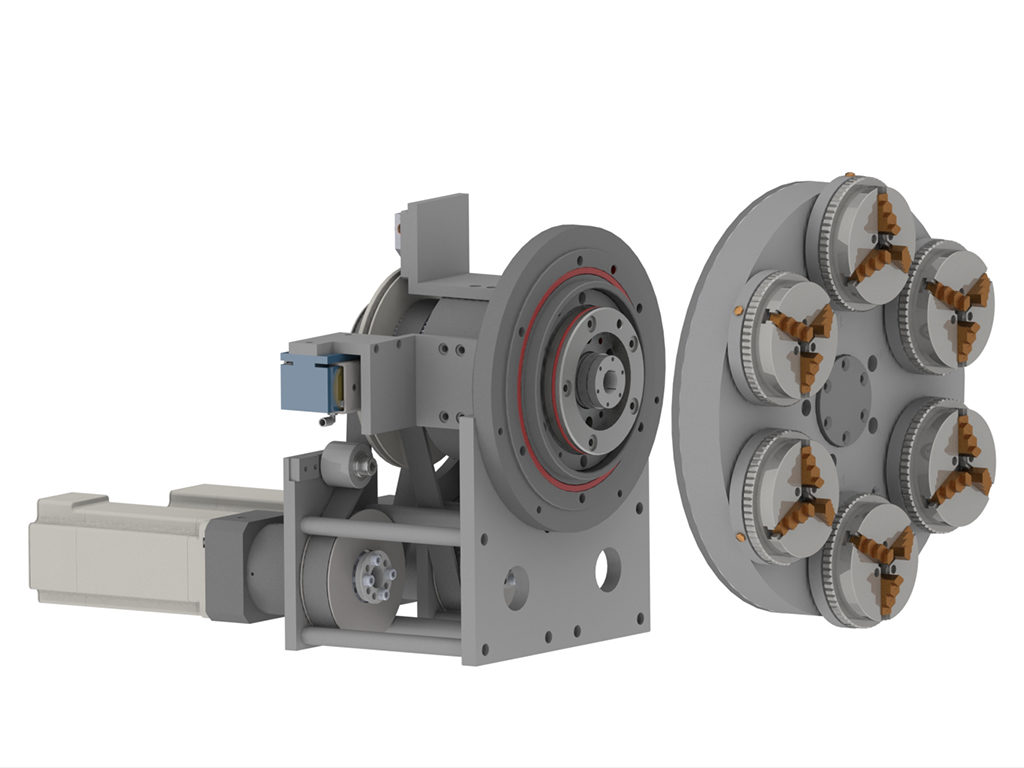

In order to serve our customers with the best suitable solution for their processes or products, the machine concept is based on modular building blocks.

This means one can choose between different laser sources and optics from a range of suppliers.

In addition, we offer customized solutions with the possibilty to integrate your existing laser. In some cases even the optics can be used.

Please contact us for further information.

CNC System

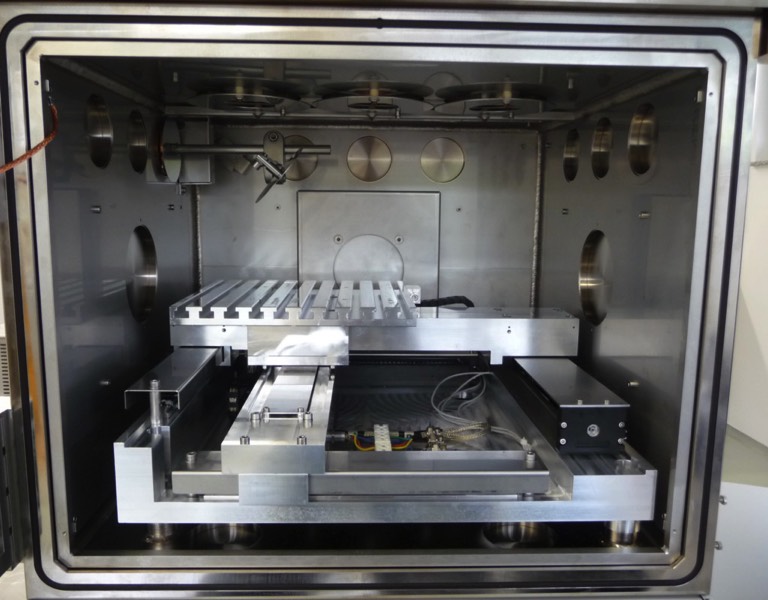

For high-precision processing an exact workpiece manipulation is necessary. In order to achieve this, we have developed a CNC system with position accuracy better than 30 µm and a movement speed of up to 100 mm/s. For reduced maintenance, the stepper motors are located outside the chamber.

Whenever the workpiece requires axial or radial welding we offer different rotary manipulators which are fully integrated into the CNC control unit.

Extras

A customized work piece fixture is very important. We offer standard devices like three-bracket chucks in different sizes or customized solutions that fits your needs including for example a 6-chuck revolver mount.

The measurement of the temperature is possible with thermocouple bushing.

Specifications

| Spezification | LaVa L8 | LaVa L95 |

|---|---|---|

| Laser | Fibre or Disc | Fibre or Disc |

| Beam Power | 500 W SM up to 2 kW MM | 500 W SM up to 6 kW MM |

| Beam guide system | Light conducting cable | Light conducting cable |

| Focal position alignement | manual or integrated in CNC system | integrated in CNC system |

| Focus traveling distance | 100 mm | 200 mm |

| Working chamber dimension | Ø235 mm x 200 mm | 500 x 500 x 400 mm ³ |

| Work piece dimension | Ø100 mm x 150 mm | 250 x 230 x 170 mm³ |

| Linear speed | 0.1 to 100 mm/s | 0.1 to 100 mm/s |

| Rotary speed | from 0.1 to 1000 rpm continuously adjustable | from 0.1 to 100 rpm continuously adjustable |

| Position accuracy | < 30 µm | < 30 µm |

| Pump down time | approx. 30 seconds | approx. 60 seconds |

| Foot print | 2 m x 2 m (angled setup) or 1 m x 3 m (straight setup) | 2 m x 2 m (angled setup) or 1 m x 3 m (straight setup) |

| Power Supply | 230V / 3.6 kW, single phase (500W Laser) 400V / 4.6 kW, triple phase (1kW or 2kW Laser) | 400V / min. 4.6 kW, triple phase (depends on Lasers power requirements) |

| Gross Weight | approx. 350 kg | approx. 750 kg |

Further Information:

LaVa Flyer

Physics Procedure

Laser Community (german)

Laser Community (english)

Application Note RWTH Aachen