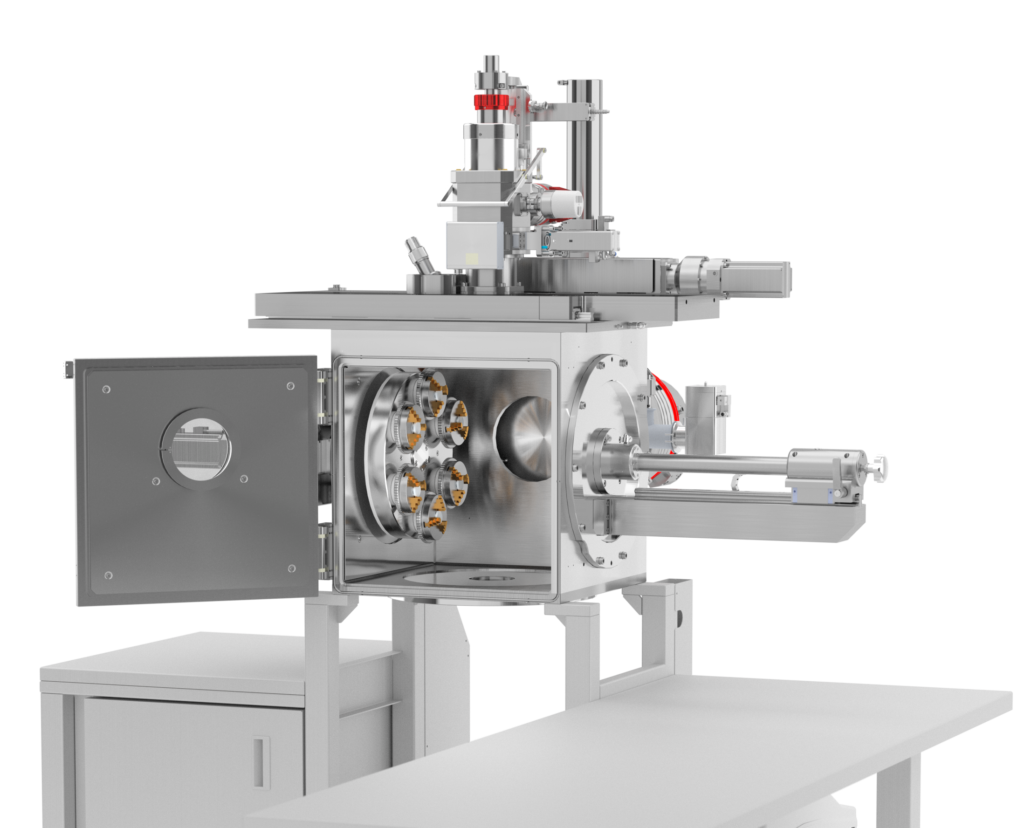

The most recent version of the MEBW-60 family, the L135, is a unique tool combining precise electron beam power control down to the µm-range with high productivity and ultimate flexibility.

The most recent version of the MEBW-60 family, the L135, is a unique tool combining precise electron beam power control down to the µm-range with high productivity and ultimate flexibility.

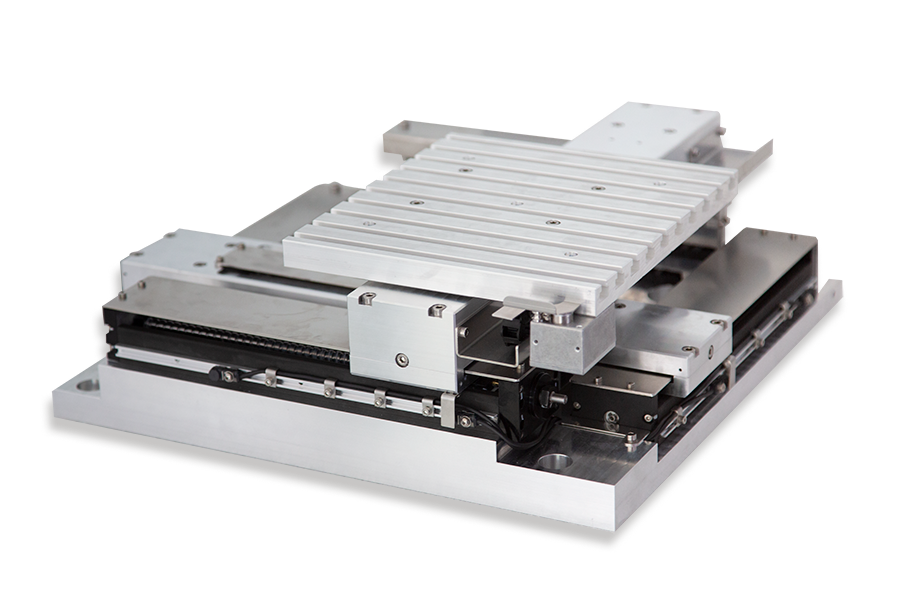

The MEBW-60 L135 is equipped with either a CNC driven bottom mounted x/y table or with a side mounted rotary manipulator. Conversion from a large single-drum into a six-drum rotary manipulator for high throughput and batch processing is very convenient. The optional egun-shift solution allows for maximum positioning flexibility.

Workpiece observation is realized with the unique FOCUS SEM Mode “Scan & View” or by traditional optical means using a camera/lens system combination. A low maintenance pumping system with high pumping speed allows for very fast turnaround cycles.

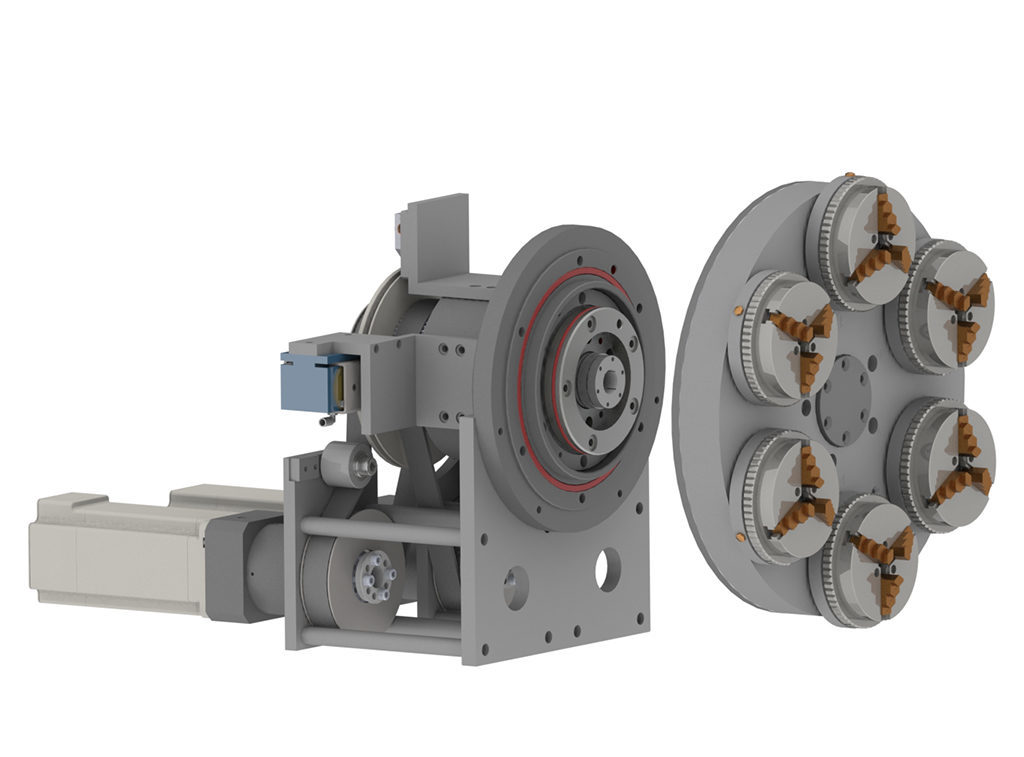

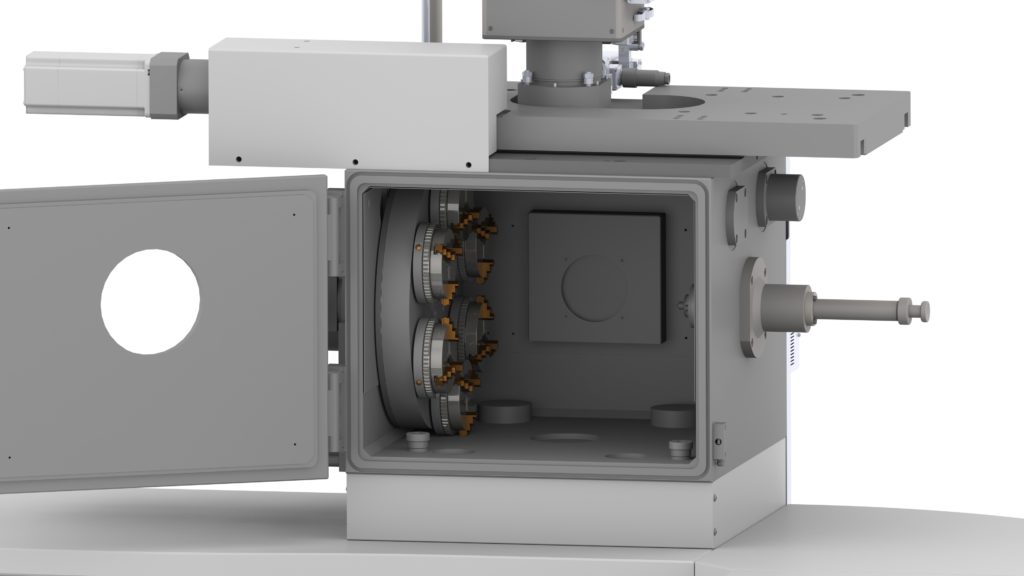

Multi drum rotary motion manipulator:

A modular multi drum rotary motion manipulator has been developed to allow welding of either one, six or even twelve workpieces within one vacuum cycle. The drive unit is mounted vertically or horizontally outside to the chamber. Inside the chamber, the drive unit can be equipped with either a one, a six or even a twelve fold rotary work piece holder.

An easy to use tooling helps to change quickly between different configurations. The motion is equipped with two motors for rotation and indexing and allows fastest cycle times. The devices can also be ordered with a tail stock or counter bearings.

Generator Slide:

The new generator slide allows for individual lateral

positioning of the power beam in the vacuum chamber. In combination with the

fixed mounted rotary motion manipulators, the generator slide allows for

flexible beam positioning for radial or axial welds. Multiple radial or axial

welds within one vacuum cycle is possible.

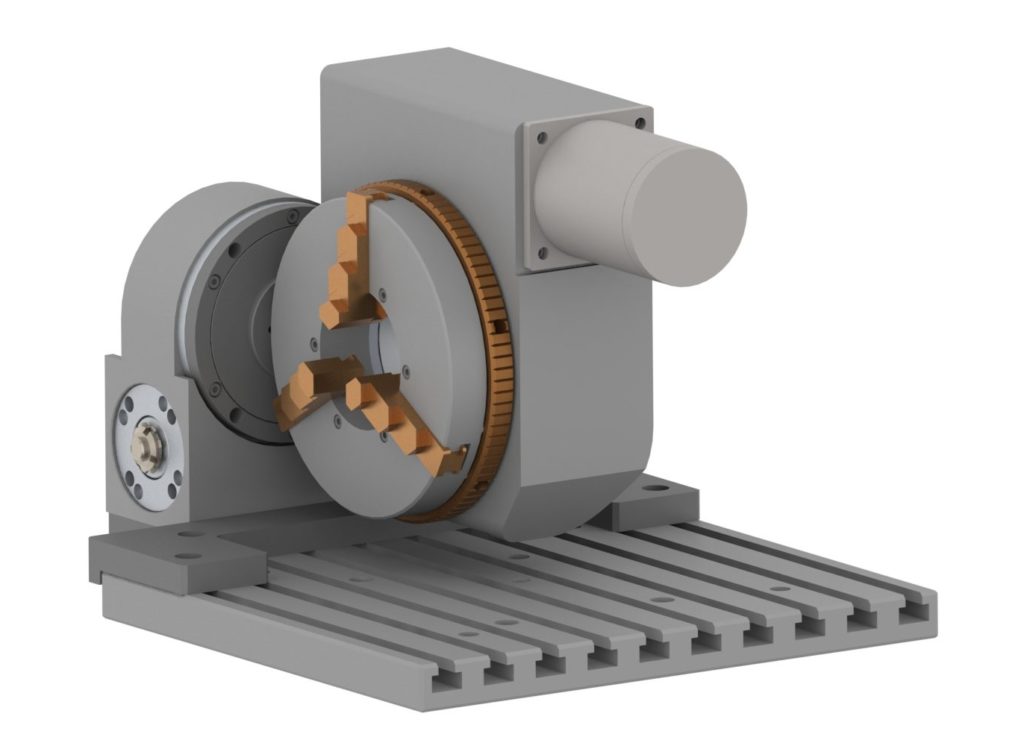

Turning- & Tilting Motion:

The modular tilt and turning device allows an angled position of the turning device for radial or axial welds. The tilting of the turning device allows for easy excess to fillet welds or other special welding geometries. This device includes several unique features, making it a more versatile tool for micro manipulation and welding. The devices grant a tight specification. Together with the minimized backlash and in combination with a precise x- y- table, free 3D interpolated workpiece positioning for welding or surface treatment becomes possible. Furthermore the turning device has a wide inner passage. This allows an easy manipulation and welding of long shafted rotational parts. Finally the devices are modular and easy to disassemble to be used separately.