Careful, clean and vacuum tight processing for sensors

The high requirements for joints of electronic components as to be vacuum-tight and high temperature resistant or a nice and smooth look can easily be fulfilled by electron beam welding.

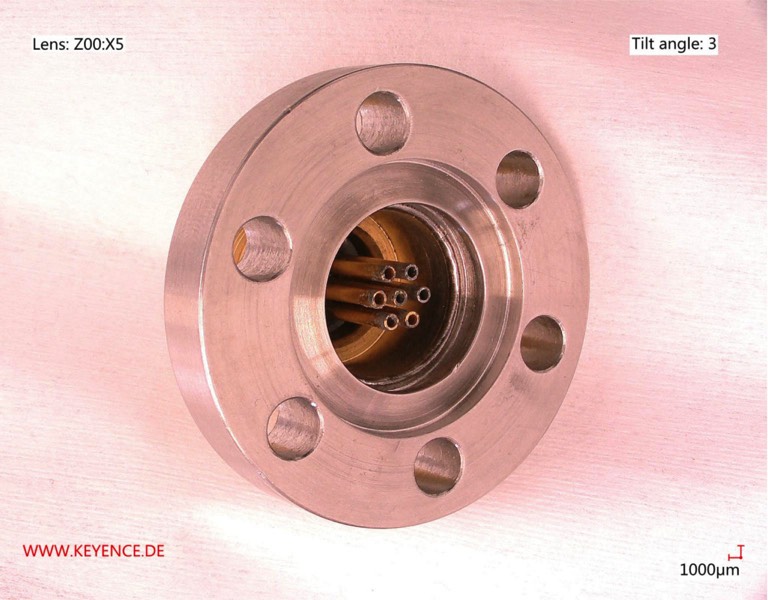

Welding of sensor housings

Fine small welding seams in the sub-mm range for sensor housings are important to minimized heat impact to the work peace.

This prevents heat sensitive parts outside the weld joint, as for example integrated electronic components, to heat up beyond critical temperatures.

In addition some sensors require to be UHV-tight encapsulated which is well achieved with e-beam welding.

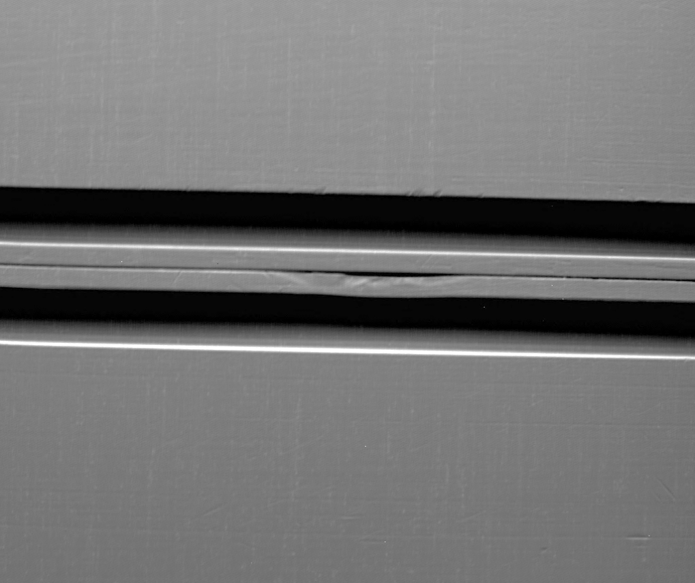

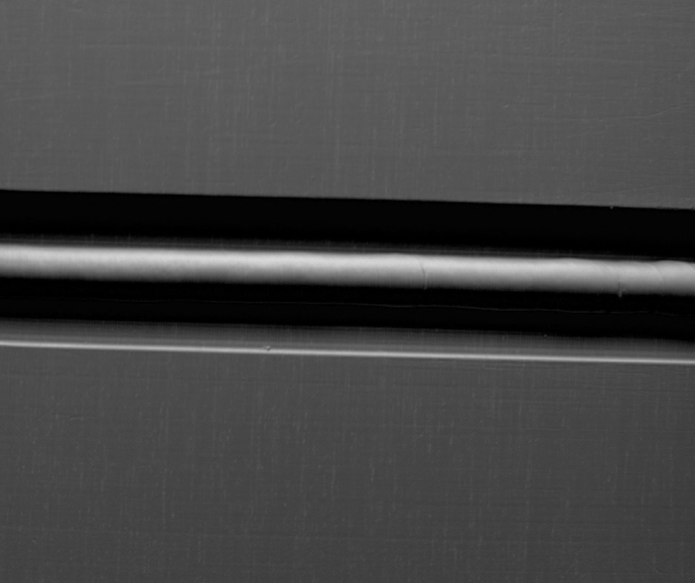

Micro welding of tubes for sensor technology:

Above: Welding of tubes to sensor body (both stainless steel):

Welding of sensor housing, Aluminum AW2024

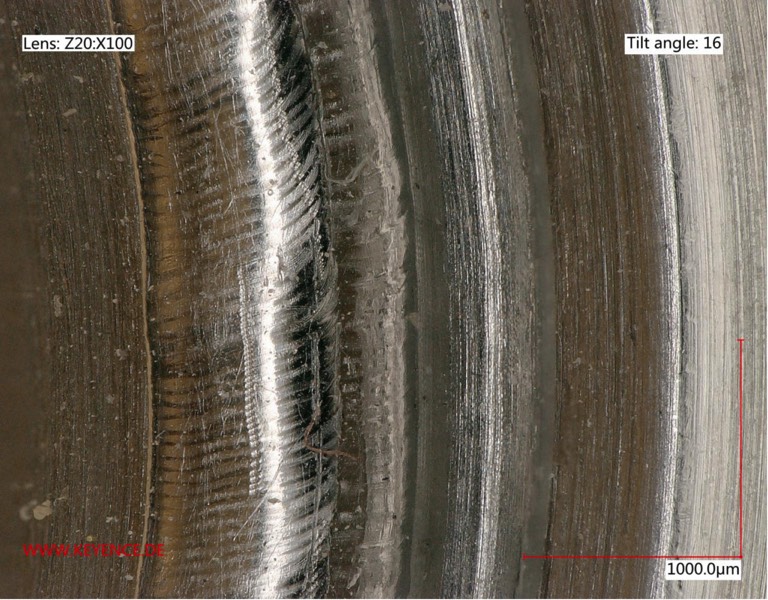

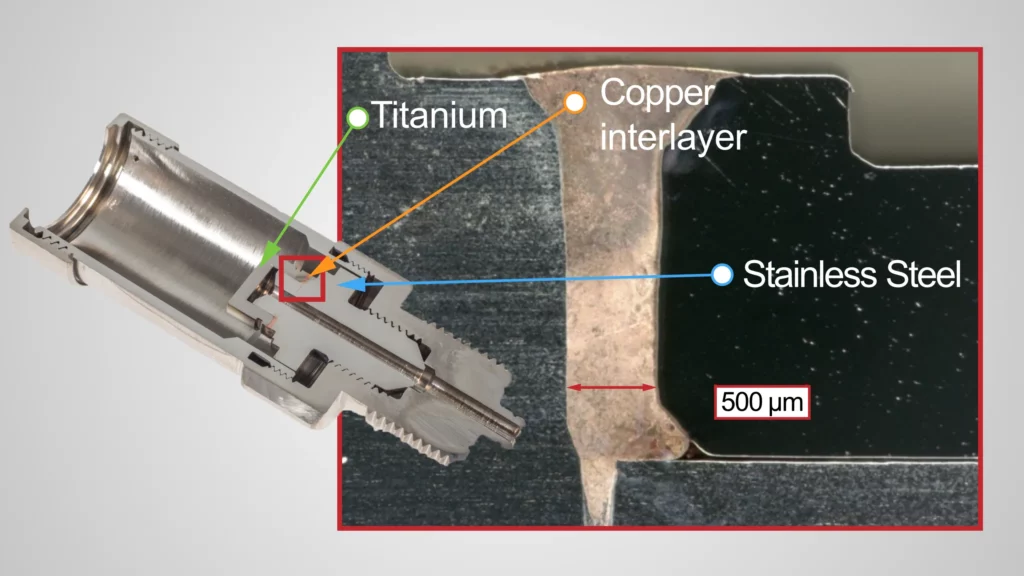

Dissimiliar Welds

Micro welding of dissimilar metals with electron beam

Joining Stainless Steel with Titanium is technological relevant but intermetallic phases prevent strong joints. For welding of sensor housing an intermetallic layer of copper with perfect beam power control is a way out.

The combination of steel to copper, gold to stainless steel or even zirconium to stainless steel are well possible with the exact alignment of the fusion zone.

Below: Dissimilar weld, stainless steel to Kovar for green technology.